Textile terms like twill, satin, and plain weave describe common fabric structures. Plain weave is the simplest, with an over-and-under pattern, giving a flat, even surface. Twill weaves create diagonal lines, making fabrics durable and slightly textured. Satin weaves produce a smooth, glossy surface with fewer interlacings, giving a luxurious feel. Understanding these basics helps you identify fabrics and their uses, and exploring further reveals how these weaves influence fabric performance and appearance.

Key Takeaways

- Plain weave is the simplest fabric structure with an over-and-under pattern, offering durability and even dye absorption.

- Twill weave features diagonal lines, providing a textured, strong, and resistant fabric suitable for workwear like jeans.

- Satin weave has a smooth, glossy surface with floating yarns, giving a luxurious appearance and soft feel.

- These weaves differ in texture, appearance, durability, and typical applications such as clothing, upholstery, and luxury textiles.

- Recognizing weave types involves examining surface patterns: plain is uniform, twill shows diagonal ridges, satin appears shiny and smooth.

What Is Plain Weave?

Have you ever wondered what makes plain weave one of the simplest and most common fabric weaves? Its straightforward over-and-under pattern has been used for centuries, dating back to ancient civilizations, making it one of the earliest textile techniques. During fabric dyeing, plain weave fabrics absorb dyes evenly, resulting in consistent coloration. Its historical origins can be traced to early cultures like Egypt and China, where the technique was essential for producing durable textiles. Today, plain weave remains popular because it’s easy to produce, versatile, and durable. This fundamental weaving method creates a balanced, flat surface, making it ideal for everything from clothing to household textiles. Its simplicity and long history have cemented plain weave as a cornerstone in textile production worldwide. Additionally, understanding the woven structure of plain weave helps in selecting the right fabric for specific applications.

Characteristics of Twill Fabric

What sets twill fabric apart from other weaves is its distinctive diagonal pattern, which results from the way the threads are woven together. This weave pattern creates a textured surface that’s durable and resistant to wear. Because of its structure, twill fabric often has a soft, flexible drape, making it suitable for clothing that needs to move comfortably. The diagonal lines give the fabric a unique visual appeal, and the weave’s tight construction enhances its strength and longevity. Twill fabrics are less prone to wrinkling, so they stay neat longer. Overall, their characteristic weave patterns contribute to a fabric that’s both practical and visually interesting, ideal for garments like jeans, chinos, and workwear. Durability is one of the key benefits that makes twill fabrics a popular choice for everyday clothing.

Features of Satin Weave

Satin weave is distinguished by its smooth, glossy surface, which results from the way the threads are woven tightly and with fewer interlacings. This technique allows the fabric to reflect light beautifully, giving it an elegant appearance. As a result, satin is highly valued in luxury textiles, often used for high-end garments, evening wear, and bedding. Its luxurious feel and shiny finish make it a favorite among designers seeking sophistication. Historically, satin weave has held significant cultural importance, symbolizing wealth and status across various civilizations. Its ability to create a sleek, lustrous surface has kept it relevant for centuries, cementing its place in both fashion and textile history. You’ll notice that satin’s features continue to define its allure today. Additionally, the luxurious feel and shiny finish of satin make it especially popular in the realm of high-end fashion and home decor.

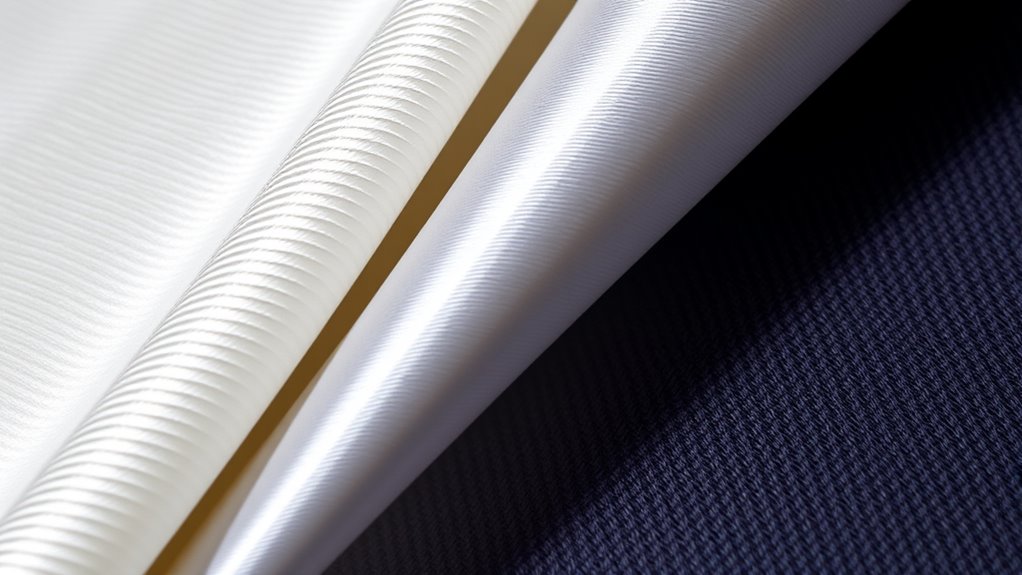

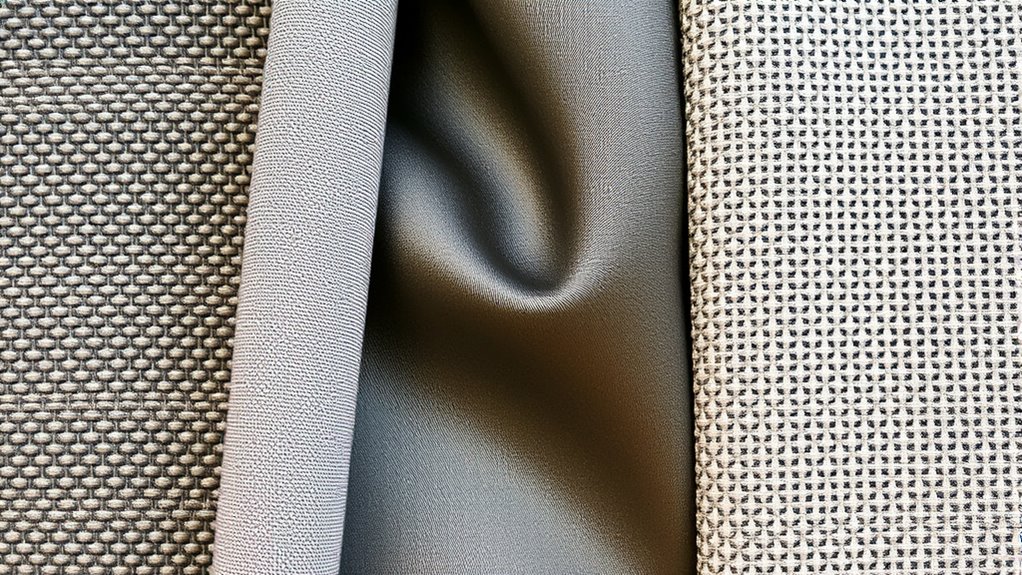

Comparing the Visual Appearance of Weaves

Different weaves create distinct visual effects that can considerably influence the overall appearance of a fabric. For example, a plain weave offers a simple, uniform surface, while twill weaves produce diagonal lines that add depth. Satin weaves have a smooth, glossy surface with fewer visible interlacings, giving a luxurious look. Fiber dyeing techniques, like yarn dyeing or piece dyeing, also impact visual appeal by affecting color depth and pattern clarity. Manufacturing techniques, such as the number of yarns per inch or the tension used during weaving, further influence how the weave looks. These factors combined determine whether a fabric appears matte or shiny, textured or sleek, and how well it showcases color and pattern. Understanding these differences helps you choose the right weave for your desired aesthetic.

Texture and Feel of Different Weaves

You can feel the surface texture and see how the appearance varies between different weaves, affecting the fabric’s overall look. Softness and comfort levels depend on the weave’s structure, influencing how it feels against your skin. Durability and wear resistance also differ, making some weaves better suited for everyday use than others. Additionally, the weave pattern plays a significant role in determining the fabric’s overall texture and visual appeal.

Surface Texture and Appearance

Have you ever noticed how the surface texture of a fabric can influence its overall feel and appearance? The weave determines whether the surface is smooth, textured, shiny, or matte. For example, satin offers a glossy, luxurious surface, while plain weave feels crisp and even. Fiber composition affects how light reflects and how dye penetrates, impacting color vibrancy and surface sheen. A tightly woven fabric with high filament fibers tends to have a smoother, more lustrous surface, whereas looser weaves may feel rougher. Here’s a quick comparison:

| Weave Type | Surface Texture | Appearance |

|---|---|---|

| Satin | Glossy, smooth | Shiny, elegant |

| Twill | Textured, diagonal | Durable, rich |

| Plain | Flat, even | Crisp, matte |

Understanding these details helps you choose fabrics with the desired look and feel. Additionally, the surface texture can influence the durability and maintenance requirements of the fabric, making it an essential factor in material selection.

Softness and Comfort Levels

The softness and comfort of a fabric largely depend on its weave, as some structures naturally feel more gentle and flexible against the skin. Fiber softness plays a significant role—softer fibers create a more luxurious feel, enhancing comfort. The way a fabric drapes also influences its comfort level; fabrics with good drape tend to move smoothly and feel gentle when worn. For example, plain weaves often feel crisp but can be less soft, while satin weaves are smoother and more supple. Twill weaves, with their diagonal lines, tend to offer a good balance of durability and softness. Ultimately, choosing a weave with soft fiber content and a fluid fabric drape ensures a comfortable, pleasant wearing experience.

Durability and Wear Resistance

Different weaves offer varying levels of durability and wear resistance, directly affecting how well a fabric withstands daily use. Twill fabrics, created with diagonal weaving techniques, tend to be more durable and resistant to abrasion, making them ideal for workwear. Satin weaves, with their smooth surface, often show less wear but can snag more easily, affecting longevity. Plain weaves are generally sturdy but may wear faster with heavy use. The weaving techniques influence fabric color variations as well; tighter weaves often hold dye better, maintaining vibrant hues longer. Choosing the right weave depends on your needs for durability and appearance. Keep in mind that a fabric’s wear resistance isn’t just about the weave but also about the quality of the fibers used. Additionally, the fabric’s construction can influence how well it withstands repeated washings and heavy use.

Durability and Strength of Each Weave

You’ll notice that some weaves, like twill, offer high durability and resilience, making them ideal for long-lasting garments. In contrast, satin and plain weaves provide moderate strength, suitable for lighter or decorative fabrics. Understanding these differences helps you choose the right weave for your specific needs.

Twill: High Durability and Resilience

Twill fabric is renowned for its exceptional durability and resilience, making it a popular choice for workwear and heavy-duty applications. Its strength stems from the unique weaving pattern, where diagonal lines create a sturdy structure. This pattern allows the fabric to withstand frequent wear and laundering without losing integrity. During fiber dyeing, the fibers are often dyed before weaving, ensuring color durability even after repeated use. The weaving patterns in twill distribute stress more evenly across the fabric, enhancing its toughness. Because of these features, twill resists tearing and fraying better than other weaves, making it ideal for demanding environments. Its high durability and resilience are what make twill a trusted fabric for work garments, jeans, and outdoor gear. Additionally, ongoing research into AI safety measures aims to improve manufacturing processes and quality control in textile production, further enhancing fabric performance.

Satin & Plain: Moderate Strength

Have you ever wondered how satin and plain weaves compare in strength? Both are known for moderate durability, making them suitable for various textile manufacturing applications. Satin weave, with its floating yarns, creates a smooth surface but can be less resistant to wear over time. Conversely, plain weave is more balanced, offering better resistance to tearing and abrasion. When fabric dyeing, plain weave fabrics tend to hold dyes evenly, enhancing colorfastness. Satin’s glossy finish may be affected by repeated laundering, impacting durability. Keep these points in mind:

- Satin’s floating yarns can lead to snags and weaker spots

- Plain weave’s tight structure offers more resilience

- Both weaves suit different textile manufacturing needs for moderate strength

- The choice of weave can influence the fabric’s durability and performance over time

Common Uses for Each Weave Type

Different weave types are chosen for their specific properties and suitability for various applications. For example, plain weave fabrics are durable and easy to dye, making them ideal for everyday clothing, upholstery, and accessories. Twill weaves, with their diagonal pattern, are favored for workwear like jeans and durable fabrics such as canvas. Satin weaves provide a smooth surface, perfect for luxury garments, bedding, and evening wear. Understanding the historical origins of these weaves helps explain their traditional uses; for instance, satin’s origins in silk production made it suitable for elegant garments. When selecting a weave, consider how its structure influences fabric dyeing, colorfastness, and overall appearance, ensuring your choice aligns with the intended purpose and aesthetic. Additionally, fabric dyeing techniques are often impacted by the weave type, affecting the final look and durability of the textile.

How Weaves Affect Fabric Performance

The structure of a weave directly influences how a fabric performs regarding strength, durability, and flexibility. Different weaves impact fiber dyeing options and overall textile sustainability. For example, a plain weave offers durability but may limit dyeing techniques, while twill weaves provide flexibility and better drape. Satin weaves produce smooth surfaces ideal for high-quality finishes, affecting fiber dyeing outcomes. Consider these points:

- Strength and durability depend on the weave’s tightness and interlacing pattern

- Flexibility and drape influence comfort and garment longevity

- The weave choice impacts sustainable practices like fiber dyeing efficiency and resource use

- The weave structure also determines how well a fabric can withstand repeated wear and washing, influencing its lifespan and overall sustainability

Choosing the right weave can enhance textile sustainability by reducing waste and optimizing fiber dyeing processes, making your fabrics more eco-friendly and long-lasting.

Tips for Identifying Weave Types in Textiles

Identifying weave types in textiles involves examining the fabric’s surface and structure to recognize distinctive patterns. Look closely at the way the threads interlace and how the surface feels. For example, a plain weave has a uniform, grid-like appearance, while twill shows diagonal ridges. Satin weave creates a smooth, shiny surface due to floating yarns. During textile manufacturing, understanding fiber dyeing techniques helps predict how colors will appear in different weaves. If fibers are dyed before weaving, colors tend to be consistent, making pattern recognition easier. When analyzing a fabric, consider the texture, pattern, and sheen. Recognizing these clues allows you to accurately identify weave types, which is essential for selecting the right fabric for your project or understanding its quality.

Frequently Asked Questions

Which Weave Type Is Most Breathable for Clothing?

You’ll find that plain weave fabrics are most breathable for clothing because they allow more airflow compared to twill and satin weaves. When considering breathability comparisons, plain weave offers better fabric comfort factors, making it ideal for hot weather or active wear. Its open, simple structure guarantees better ventilation, helping you stay cool and comfortable throughout the day. So, if breathability is your priority, go for plain weave fabrics.

How Does Weave Influence Fabric Stretchability?

You’ll notice that the weave impacts fabric stretchability by how it influences fiber elasticity and stretch recovery. Looser weaves, like plain weave, allow more movement, making the fabric more stretchable. Tighter weaves, such as satin or twill, restrict stretching but offer better shape retention. Your choice depends on whether you prioritize flexibility or durability. Always consider fiber elasticity and stretch recovery to assure the fabric meets your comfort and performance needs.

Are Certain Weaves More Eco-Friendly to Produce?

You’ll be amazed how some weaves are way more eco-friendly to produce! For example, plain weave often uses less water and energy, making it a sustainability superstar. Natural fiber weaves like hemp or organic cotton also dramatically cut environmental impact. By choosing these, you reduce waste and conserve resources. So, yes, certain weaves not only look great but also champion sustainability, helping you make a more environmentally responsible choice.

Can Weave Patterns Be Combined in a Single Fabric?

Yes, you can blend patterns in a single fabric, creating interesting textures and visual effects. Combining weave patterns like twill and plain weave can enhance fabric durability while adding unique style. When you blend patterns, make sure they complement each other and don’t compromise the fabric’s strength. This technique allows you to experiment with textures, making your textiles both functional and aesthetically appealing.

How Do Weaves Affect Dye Absorption and Color Vibrancy?

You’ll notice that the weave affects how dye penetrates and the fabric’s color vibrancy. Tighter weaves, like plain weave, often improve dye absorption, leading to more vivid colors, while looser weaves might require dye penetration techniques to guarantee even coloring. The weave also influences colorfastness because some structures better lock in dye, resulting in durable, vibrant fabrics. Choosing the right weave helps you achieve consistent, long-lasting color in your textiles.

Conclusion

Understanding the differences between plain weave, twill, and satin helps you choose the right fabric for your needs. For example, twill fabrics are known for their durability, with some denim jeans lasting over 10 years with proper care. Recognizing these weaves guarantees you select textiles that match your desired look, feel, and performance. By mastering these details, you’ll make smarter, more informed choices in your fabric selections and sewing projects.