LED strip lighting operates by utilizing LED diodes placed on a pliable circuit board that effectively distributes power and manages the flow of current. This arrangement produces vibrant, energy-efficient light that is well-suited for a variety of applications. Voltage regulation ensures a steady power supply, while current-limiting resistors safeguard the LEDs from damage. The protective casing shields the components, and the adhesive backing helps with secure attachment. The operation of LED strip lighting is efficient, providing customizable illumination with a range of color options. Familiarity with the components and functions of LED strip lights unveils the intricate mechanisms behind this adaptable lighting solution.

Key Takeaways

- LED diodes emit light when powered by the circuit board.

- Current-limiting resistors regulate voltage to protect LEDs.

- Circuit board ensures even power distribution for consistent lighting.

- Semiconductor materials determine the color of the light emitted.

- LED density impacts the brightness of the lighting.

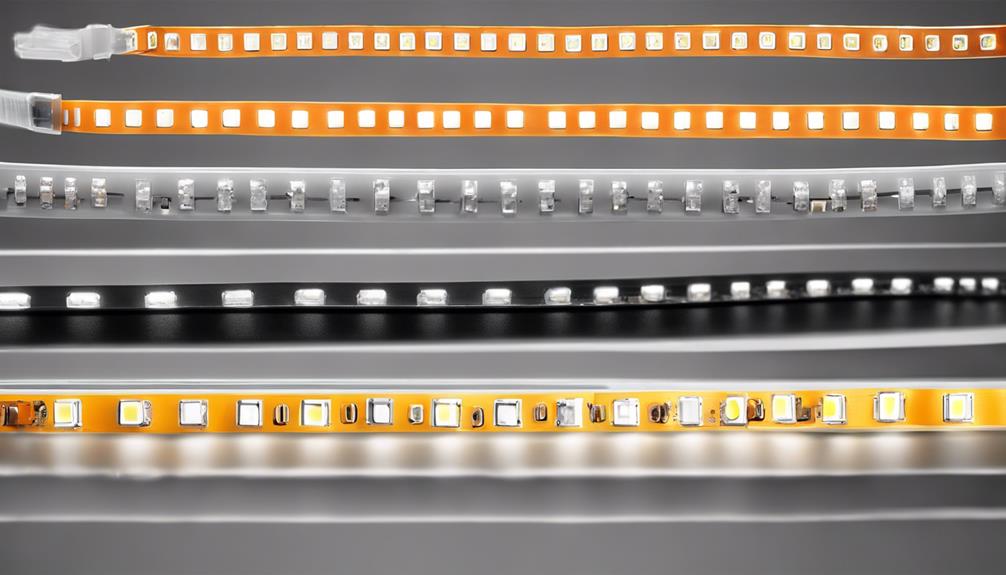

LED Strip Components

LED strip lighting incorporates individual LED diodes mounted on a flexible circuit board to create a versatile and energy-efficient lighting solution. The flexible circuit board allows the strip to bend and contour to various shapes, making it ideal for decorative and practical lighting applications. The adhesive backing, often using 3M tape, provides a convenient way to install the strip on different surfaces, ensuring a secure attachment.

One vital component of LED strip lighting is the voltage regulation. The flexible circuit board distributes power evenly to each LED along the strip, preventing voltage drops that could impact the brightness and lifespan of the LEDs. Current-limiting resistors play a key role in regulating the voltage, protecting the LEDs from potential damage due to fluctuations in power supply. Additionally, the protective casing shields the components from environmental factors like dust and impacts, ensuring the longevity and durability of the LED strip lighting system.

LED Diodes and Circuit Board

The integration of LED diodes and a flexible circuit board in LED strip lighting enables efficient distribution of power and customization in mounting options.

LED diodes, the essential components of the strip, emit light when an electrical current passes through them. The circuit board plays a vital role in distributing power evenly to each LED diode along the strip, ensuring uniform illumination. Additionally, LED diodes are coated with epoxy resin for protection against external elements, increasing their durability and lifespan.

The circuit board also allows for flexibility and customization in mounting the LED strip, offering users various ways to install and showcase the lighting. Furthermore, current-limiting resistors integrated into the circuit board regulate voltage, preventing LED damage and ensuring consistent performance.

Current-Limiting Resistors

Regulating the voltage supplied to each LED on the strip, current-limiting resistors play an important role in maintaining peak performance and preventing damage in LED strip lighting systems. These resistors guarantee that the LEDs receive the appropriate amount of current, safeguarding them from potential harm and extending their lifespan. By calculating the resistance value based on the LED's forward voltage and the desired operating current, these components help achieve consistent and safe operation of the LEDs.

Without current-limiting resistors, LEDs are at risk of experiencing thermal runaway or burnout due to excessive current flow, which can lead to permanent damage. Hence, the inclusion of these resistors is critical in protecting the LEDs and optimizing the overall performance of the lighting system. Properly selected and implemented current-limiting resistors are essential for the efficient and reliable operation of LED strip lighting.

Protective Casing and Adhesive

The protective casing of LED strip lights shields components from weather, dust, and impacts, ensuring durability.

Adhesive backing, often 3M tape, allows for easy installation on various surfaces without the need for additional tools.

The combination of protective casing and adhesive backing makes LED strip lights versatile for both indoor and outdoor applications.

Casing for LED Strips

Shielding LED components from weather, dust, and impacts, protective casing guarantees the durability and longevity of LED strip lighting installations. LED strip casing, also known as protective casing, plays an important role in outdoor settings by providing resistance against moisture and environmental elements.

The adhesive backing, often in the form of 3M tape, facilitates easy and secure mounting on various surfaces without requiring additional tools. This adhesive backing ensures a strong bond between the LED strip and the mounting surface, preventing peeling over time.

Proper alignment of copper pads and connectors is essential when connecting LED strips to maintain electrical connections and prevent damage. By incorporating these elements, the casing enhances the overall performance and lifespan of LED strip lighting systems.

Adhesive Strength

Ensuring a strong and lasting bond between the LED strip and the mounting surface, the adhesive backing plays an essential role in maintaining the stability of installations. LED strip lights typically feature a robust 3M adhesive backing that securely attaches the strip to various surfaces, preventing peeling or detachment.

For enhanced adhesive strength and longevity, it's important to thoroughly clean and dry the mounting surface before application. To reinforce the installation further, using mounting clips or tracks in conjunction with the adhesive backing is recommended for a more permanent and durable setup.

Proper alignment of copper pads and connectors when joining strips is essential to preserve the integrity of electrical connections, safeguarding against damage during installation.

Connecting Wires and Power

LED strip lights require proper wire connections to a compatible power supply, ensuring the LEDs illuminate effectively.

Maintaining correct polarity during the wiring process is essential to prevent any potential damage to the LED strip.

Safety considerations play a key role in setting up the connection to guarantee a safe and efficient lighting system.

Wire Connection Basics

Proper wire connections are vital for the functionality of LED strip lights. When connecting wires to the power supply, ensuring the correct polarity is essential to prevent damage to the LEDs.

Parallel connections are commonly used to power multiple LED strips from a single power supply, allowing for synchronized lighting effects. It's important to create secure and well-insulated wire connections to maintain the safety and longevity of the LED strip lighting system.

Power Supply Requirements

When establishing a reliable LED strip lighting system, attention to power supply requirements for connecting wires and power is essential. LED strip lights typically operate on 12V or 24V DC power supplies to guarantee proper functionality.

It's important to use connecting wires with the correct polarity to avoid damaging the LEDs in the strip. To power multiple LED strips, connecting them in parallel to a suitable power supply is recommended for extended lighting setups.

Limiting the length of LED strips can help prevent excessive voltage drop, ensuring uniform brightness throughout the installation. Additionally, utilizing an LED controller allows for customization of lighting effects and brightness levels based on individual preferences.

Safety Considerations

To guarantee safe and efficient operation of LED strip lighting installations, attention to proper connection of wires and power is crucial. When connecting wires, confirm correct polarity to prevent damage to the LEDs.

It's essential to use a power supply that matches the voltage and wattage ratings of the LED strips to maintain safe operation. For multiple LED strips, consider connecting them in parallel to a suitable power supply to evenly distribute power and avoid overloading.

Be mindful of the length of LED strips to prevent excessive voltage drop, ensuring consistent brightness throughout the installation. Incorporating an LED controller not only allows for customization and dimming options but also helps maintain safety and efficiency in LED strip lighting setups.

Light Production Mechanism

LED strip lighting guarantees light by passing electricity through a circuit board, activating individual LED diodes to emit light evenly across the strip. Each LED diode on the strip is a semiconductor device that produces light when current flows through it. The circuit board ensures that the electrical current is distributed uniformly to all the LED emitters, resulting in consistent lighting output.

The specific materials used in the semiconductor of the LED diodes determine the color of the light they emit. For instance, different semiconductor materials can produce a variety of colors ranging from warm whites to cool blues. Additionally, the density of LEDs on the strip impacts the overall brightness of the lighting. Higher LED density leads to a more luminous output, making the area illuminated by the strip brighter.

This mechanism of light production in LED strip lighting allows for efficient and customizable illumination in various settings.

Installation Tips and Tricks

After understanding how LED strip lighting operates by activating individual LED diodes through a circuit board, attention shifts to practical Installation Tips and Tricks for ensuring peak performance.

When installing LED strips indoors, it's important to clean and dry the mounting area thoroughly before applying the strip to guarantee ideal adhesion. Using mounting clips or tracks can help reinforce the adhesive, providing a permanent fixed installation that stays in place.

When joining LED strips, aligning the copper pads and connectors is critical to prevent damage and ensure proper functionality.

For outdoor installations, employing waterproof casings and securely fixing the LED strips to surfaces is crucial to protect against weather damage. Proper placement and adhesion of LED strips are key factors in ensuring they remain secure and can withstand various weather impacts.

Benefits of LED Strip Lighting

LED strip lighting revolutionizes illumination with its exceptional energy efficiency and versatile design possibilities. These innovative lighting solutions offer significant benefits, making them a popular choice for both residential and commercial applications. Below is a table highlighting the key advantages of LED strip lighting:

| Benefits | Description |

|---|---|

| Energy Savings | LED strips can provide up to 90% energy savings compared to traditional incandescent bulbs. |

| Long Lifespan | With a lifespan of over 50,000 hours, LED strips reduce maintenance and replacement costs. |

| Flexible Design | The thin and flexible form factor of LED strips allows for creative and versatile lighting designs. |

| Vibrant Lighting | LED strip lights emit consistent and vibrant lighting, enhancing the aesthetics of any space. |

Powering and Control Options

When setting up LED strip lighting, selecting the appropriate power source and control method is essential for best performance and customization. LED strip lights typically operate on 12V or 24V DC power for best brightness and efficiency.

To control the lighting effects, various options such as dimmers, remote controls, or integration with smart home systems are available, offering versatile customization possibilities. LED controllers play a key role in enabling color changes, adjusting brightness levels, and creating different lighting patterns according to preferences.

It's important to power LED strips in parallel using a suitable power supply to maintain consistent brightness throughout the strip. Proper wiring and connection of the LED strips to the power supply are crucial steps to guarantee safe and efficient operation.

Frequently Asked Questions

Do LED Strip Lights Need to Be Plugged In?

LED strip lights need to be plugged into a power source to function. They typically require a 12V or 24V DC power supply to illuminate the LEDs effectively. Ensuring a secure connection to the power supply is vital for consistent performance.

Plugging them into dimmers or controllers allows for customized lighting effects. Using the correct power source and securely connecting the strip lights is essential for safe and efficient operation.

How Do LED Strip Lights Connect to Power?

LED strip lights connect to power through a compatible power supply that matches the voltage (12V or 24V) of the strip. Proper polarity connection is essential to avoid damaging the LEDs when connecting to the power supply.

Multiple LED strips can be connected in parallel to a single suitable power supply for simultaneous operation. Limiting the length of the LED strip prevents excessive voltage drop and guarantees consistent lighting performance.

What Are the Disadvantages of LED Light Strips?

LED light strips come with drawbacks worth noting. These include:

- Initial costliness compared to traditional options

- Limited color choices

- Challenges in heat dissipation leading to reduced lifespan

- The need for extra accessories for dimming or smart control at an added expense

- Potential issues with uneven light distribution or spotting

Understanding these downsides can help users make informed decisions when considering LED strip lighting for their needs.

What Power Supply Do I Need for LED Strip Lights?

To determine the power supply needed for LED strip lights, calculate the total wattage and choose a supply that offers slightly more than 125% for best performance.

Outdoor lights require at least 200% to handle weather conditions.

Match the power supply voltage (5V, 12V, or 24V) to the LED strip lights.

Consult the manufacturer's specifications for the right power supply.

Conclusion

To sum up, LED strip lighting functions by utilizing small diodes on a circuit board to produce bright and energy-efficient light.

The current-limiting resistors help control the flow of electricity, while the protective casing and adhesive make installation easy.

With various powering and control options available, LED strip lighting offers a versatile and cost-effective solution for illuminating any space.

As the saying goes, 'bright ideas light up the room,' and LED strip lighting certainly delivers on that promise.